China’s first salt recovery crystallisation plant a success at Zenith Nantong

Date:2022/7/8 Source: CISDI

A state-of-the-art salt recovery crystallisation process is resulting in zero liquid discharge at Zenith Nantong Steel - a first for China.

Nantong’s central water treatment plant is producing salts via a critical crystallisation process, which is the first of its kind in China.

CISDI was the water plant’s EPC-based service provider and ZLD targets have been met since start-up.

Liyuan Dong, president of Zenith Nantong Steel, celebrated by hitting the salt production button, along with Nantong’s deputy chief Xuesong Zang and Zhichun Hu, CISDI’s Zenith Nantong administrative deputy chief and vice-president of CISDI Engineering Co.

Long focussed on transforming steel to green and intelligent levels, back in the early stages of planning Nantong Steel, Zenith Group voiced its determination to build China’s first ZLD plant with salt recovery crystallisation at its core.

CISDI undertook the ZLD plant’s master plan, designs and construction, focussing on a central water treatment system, plant-wide water supply and drainage pipeline network, plus a storm water collection and recycling system.

A high level of scientific, optimised expertise and equipment featured in CISDI’s total solutions:

✔ a front-facing top-level design

✔ self-sufficient water-salt balance forecast system

✔ state-of-the-art FLOC FOCUS® intelligent dosing system

✔ advanced nano-filtration crystallisation expertise

✔ sector-leading computing platform for storm collection and recycling

Source water at Nantong Steel is particularly high in mineral and salt content.

To counteract this, CISDI applied a multi-stage concentration and separation system, featuring the FLOC FOCUS® intelligent dosing system, a global-first, and advanced nano-filtration crystallisation expertise.

Waste water laden with salt is further concentrated and separated. The solution is then evaporated to produce sodium chloride, an industrial salt with a purity of 99 per cent, and the water left is converted to desalinated water - a complete recycling process.

As a result, the entire plant’s waste water discharge has been reduced by 12 million tonnes a year and all waste water is turned into resources.

CISDI’s team Chinese principles: green, genius, guarded, guiding and grace - the 5Gs.

The project is now a leader in China’s zero waste water discharge developments. CISDI’s expertise in this sector is consistently improving the green and smart credentials of numerous Chinese plants.

Nantong Steel now has its blast furnace ironmaking, BOF steelmaking and ZLD water treatment plants running, thanks to CISDI’s innovative tech and solutions.

Each plant is hitting its environmental targets for low-carbon smelting, super-clean melting and zero liquid discharge production, making Nantong Steel the benchmark for green, efficient and smart standards.

Teams unite to celebrate the commencement of salts production at the CISDI-built water treatment plant at Zenith Nantong Steel in China’s Jiangsu Province

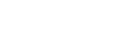

The water treatment plant, operating to high-standard green levels

Link:

Zenith Nantong Steel, a Greenfield complex still under construction, will have the capacity to become the world’s largest producer of steel.

CISDI is the primary partner for its master plan, overall designs, EPC management and the EPC-based services for its 10-plus major plants.

Nantong Steel is a green, smart champion. It operates with no liquid and solid waste discharges.

Gaseous waste emissions are 30 per cent cleaner than China’s national ultra-low emissions standard. Over 90 per cent of materials are transported by clean transport.

All its energy consumption indicators are Chinese steel sector leaders.