New era of gas-powered energy at Chongqing Steel

Date:2022/8/22 Source: CISDI

CISDI Thermal and Environmental Engineering Co has completed its task of creating a 3x80MW ultra-high-temperature, subcritical power generation unit at Chongqing Steel.

The unit is on-grid and operating with stable, high-standard indicators.

Blast furnace gas is used for the power generator. This energy recycling process has become an important player in the steel sector’s pursuit of energy conservation and carbon reduction.

UHT subcritical power generation tech achieves an advanced version of this process.

At Chongqing Steel, a primary reheating facility can effectively prevent the spread of blast furnace gas. In addition to enhancing gas availability, the UHT subcritical generation unit results in a 25 per cent higher thermal efficiency than the existing unit at the plant.

The CISDI-designed unit has scaled up the plant’s energy conservation, carbon reduction and economies.

CISDI Thermal is now focussing on wider marketing of its expertise in power generation and by-product reutilisation. Top priorities are the promotion of its high-performance, downsized power generators and coking plant excess heat recovery.

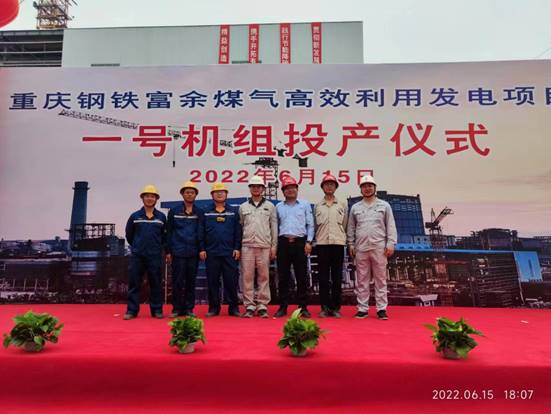

The CISDI-designed ultra-high-temperature, subcritical power generator has been successfully on grid in its first testing

A ceremony was staged to celebrate the success of the BFG power generation unit