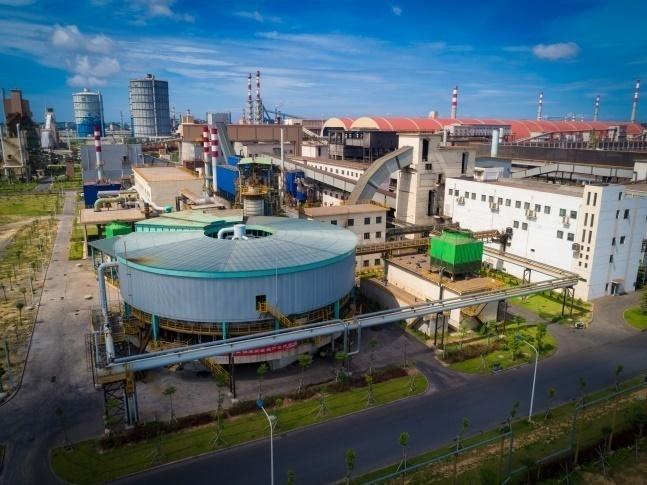

CISDI’s patented rotary hearth furnace set to solve problems for Jingtang

Date:2019/2/5 Source: CISDI

CISDI’s patented rotary hearth furnace set to

solve problems for Jingtang

CISDI is

supplying its revolutionary eco-friendly rotary hearth furnace to solve zinc waste

problems at Shougang Jingtang United Iron & Steel.

Based at

the Tangshan Caofeidian Industrial Zone in China’s Hebei Province, the plant’s

current furnace, which has an output of 300,000 tonnes,

treats zinc-bearing

solid waste and has a 150,000-tonne homogenising line.

Jingtang urgently needs to build a replacement

so it can turn its waste into resources.

Environmental regulations which came into force

in 2018 now prevent the sale of zinc-bearing solid waste. And because of the

composition of its stock materials, Jiangtang’s zinc load far exceeds the

trade’s average.

CISDI

Thermal & Environmental Engineering’s rotary hearth furnace has been

awarded over 30 patents and six project references.

Iron, zinc

and carbon solid wastes can be treated and transformed into resources. Its

design solves the industry’s chronic problem of solid waste treatment and the

difficulties of achieving a zero discharge of iron-bearing dusts.

An

open-loop recycling system for treating zinc waste will be

created, with a zero-discharge and zero-landing target.

CISDI

Thermal won the Engineering,

Procurement and Construction contract thanks to its success at Yanshan

Steel and Baowu Zhanjiang, where CISDI-designed and supplied fast ramp-up RHFs

are giving optimal production results and world-leading indicators of over 85

per cent of the final de-zincification ratio.

CISDI Thermal

is already developing other core equipment in line with the furnace’s complex

technology.

Baowu Zhanjiang’s solid waste system is China’s first metallurgical

solid waste treatment and waste-to-energy centre. Built by rotary furnace

hearth experts at CISDI Thermal, the patented technology solved the steelwork’s

iron-bearing dust treatment issue and achieved dust recycling throughout the

plant